Aluminum Geodesic Domes

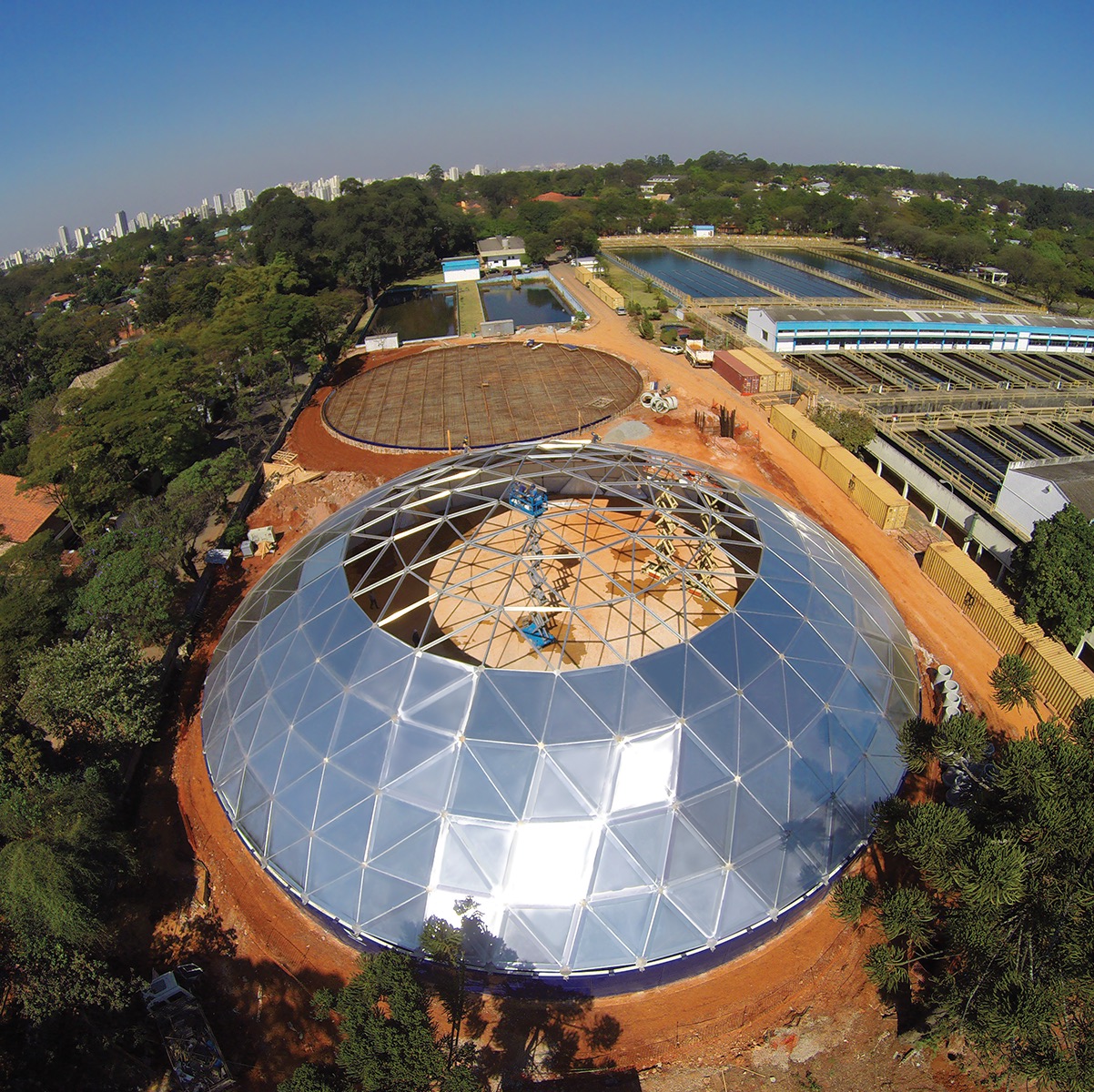

Only the EXPERTS in STORAGE CONTAINMENT could bring you Aluminum Geodesic Domes that are designed, manufactured and constructed better than competitor products. www.aluminumdomes.com

We design, manufacture and install Aluminum Geodesic Domes and storage tank covers for the following applications:

- Water and wastewater tanks

- Dry bulk Storage

- Petroleum storage tanks

- Architectural applications

Unlike other manufacturers that use subcontracted labor for field installation, Tank Connection aluminum geodesic domes and storage tank covers are installed utilizing direct factory crews. Complete turnkey design, supply and field installation by one company!

Tank Connection offers unlimited sizes ranging from 3.5m up to 304.8m

Our solution includes:

- The premier aluminum dome design

- Unmatched aluminum geodesic dome quality

- Competitive pricing

- The best warranty on materials and installation

Tank Connection Dome Advantage

- All aluminium construction

- Corrosion resistant

- Maintenance free

- Engineering excellence

- Strongest space frame design

- Clear span design

- Installation by direct factory crews

- Water tight construction

- Reduced vapor losses on internal and external floaters

- Quick field installation

- Extended service life

- Standard warranty 2 years

- Optimum cost efficiency

- Superior aesthetics

- Superior performance

WHAT MAKES THE BEST ALUMINUM GEODESIC DOME DESIGN?

- Proprietary design software, automated drawings and download files for manufacturing.

- Proprietary extrusions, struts, batten bars and node cover designs.

- The latest state-of-the-art dome fabrication equipment.

- All aluminium construction that is corrosion resistant and virtually maintenance free.

- Unmatched product quality that is backed by the best warranty in the industry.

- A dome cover that provides superior field performance and superior aesthetics.

- Available for expedited shipments worldwide.

Request Quotation

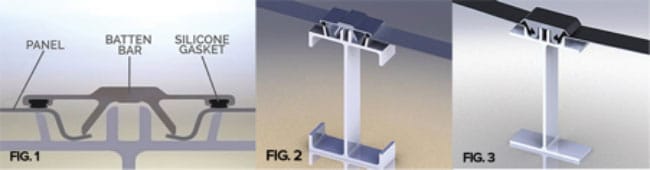

TANK CONNECTION BATTEN BAR DESIGN: FIG. 1 & 2

At AluminumDomes.com our beam design uses flange stiffeners for maximum beam strength. The batten bar attachment slot does not attempt to pre-form threads for screws that attach the batten bar to the beam, since a 6mm bolt thread pattern requires tolerances in excess of what can be extruded in aluminium. Instead this slot is sized for a thread rolling fastener that can be removed and installed multiple times in the same slot. The batten bar is designed as a leaf spring to compress the low memory set silicone gasket between the panel and the batten bar. The panel edge bend is designed such that when the batten is tightened, the panel is pushed into the gasket. This is the only batten system with three redundant features to ensure a leak free design. The batten legs are also designed to prevent twisting when personnel access the dome roof.

COMPETITOR DETAIL: FIG. 3

The attempt to form threads in the beam at the extrusion mill is not practical due to normal extrusion process tolerance. A screw will strip out the threads in the slot after one or two installations and will not develop maximum strength. No flange stiffeners are allowed due to manufacturing limitations. The gasket compression is the sole device for sealing the joint