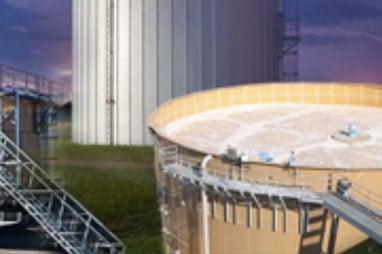

Dry Bulk Storage Solutions

Affordable Dry Bulk Storage Tanks

For the best dry bulk tank prices and the widest selection of dry bulk storage tank containers, African Tanks can assist you.

With up to 9 different types of dry bulk tanks suitable for their specific purpose, we are one of the biggest suppliers of all kinds of tanks in South Africa while we also supply tanks to the rest of the African continent. Of the tanks you can choose from, we have the biomass storage tanks, food storage tanks, plastic resin storage tanks, chemical storage tanks, AG & Meal storage tanks, power utility tanks, mineral storage tanks, flue gas desulfurization and limestone tanks and cement storage tanks. Each is designed in such a way that the contents stored will be kept in pristine condition.

Our tanks won’t break the bank when you initially purchase one or when in need of repairs and they have a phenomenal resale value. They also have a fantastic, long lifespan.

Tank Connection Affiliates

Tank Connection is one of the most trusted leaders in the manufacturing of dry bulk as well as liquid bulk storage systems. They produce the best tanks on the market, designed to meet the needs of each client. This company both designs and manufactures all of the tanks requested by customers, and then their distributors install them. This guarantees that clients receive exactly what they are looking for and as such their every storage need is met.

Through Tank Connection, African Tanks is able to provide clients with all 4 of the major types of steel tanks which include the field-welded storage tanks, hybrid storage tanks, bolted RTP tanks (rolled, tapered panel), and the shop-welded tanks. These tanks offer the ultimate turnkey solution for clients of all kinds.

Read more

You can expect to enjoy a number of benefits when you buy one of these dry bulk tanks. Regardless of your dry storage needs, the Tank Connection tanks are fantastic when it comes to meeting client expectations and fulfilling the purpose for which you have bought them. These are a few reasons why you should consider one of these tanks:

Ideal for keeping dry substances safe, these tanks are used for storing sugar, grain, wood chips, cement, plastic products, gravel, sand, various powders and corn. The bolted stainless steel tanks are particularly useful as they are both flexible and have great mobility.

Not sure of the difference between the dry option and the liquid option? Let’s clear up any confusion and answer your pressing questions.

Large tanks will always be necessary for both storing and transporting dry or liquid materials. Depending on what you will be storing in the tank, you will end up choosing a tank that meets the right criteria for the materials you will be storing. As there is such a wide variety of tanks on the market, each made to hold a specific material, you’ll find that the criteria and the actual design of the tanks will differ. While the size, units, material corrosion, foundation, composition and standards will play a role in determining the differences between the two types of tanks, it is the design that plays the biggest role of all.

The design for liquid tanks is generally as follows:

The design that is applicable to dry tanks includes:

To find out if we have the tank that you need, you can get in touch with our professional team. Our dry bulk tanks can be constructed on site. Let’s talk about your tank needs!